What are linear units?

Movements in technical mechanical systems cannot be arbitrary. They must follow a precisely defined path; otherwise you will run the risk of damage to the machine, defective products or danger to employees. Machines make use of both radial and linear movements. Radial movements are circular. Linear movements follow straight lines along a defined path of travel.

Linear units ensure that an actuator, module, or sensor moves precisely along this intended path. The linear unit reliably prevents deviations to the left, right, up, or down, assuming that no rotational capability is desired.

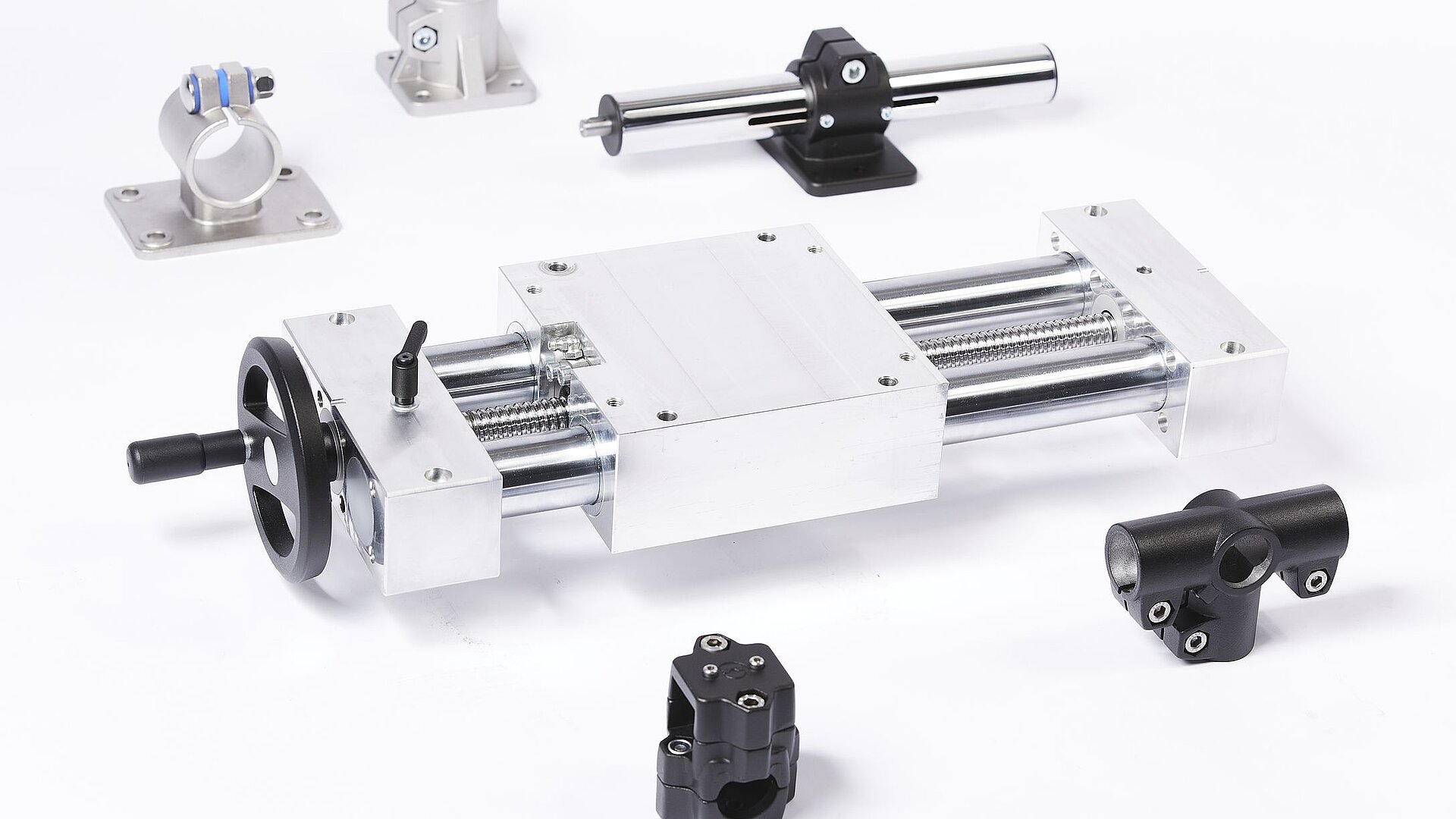

Linear units combine the guiding and driving functions into a single element. The movement can be executed manually, pneumatically, mechanically, or hydraulically.

Linear units combine the guiding and driving functions into a single element. The movement can be executed manually, pneumatically, mechanically, or hydraulically.

By combining multiple linear units, it is possible to quickly and easily assemble a multi-axis system. The reliable linear guides ensure repeatable movements for consistent quality.

Where are linear units used?

From machine construction to medical technology and the semiconductor industry – linear guides are used anywhere that defined linear movements are needed. Typical applications for linear units include: - Infeed and outfeed systems- CNC machine tools- Manipulators- High-precision measurement units.

The advantage of high-quality linear units lies above all in the reliable and repeatable precision of their start and end positions. This makes them especially useful for feeding parts into production machines. They can achieve rapid cycle times, even when executing multiple production steps in series or in parallel.

In CNC machining, linear units are used to arrive at the programmed position with the desired precision. In this way, they guarantee compliance with the specified tolerances for every milled and turned part.

Linear units also play an important role in 3D coordinate measurement systems. They ensure that the measuring head travels to the desired points with consistent precision. This makes the results of the part measurement reliable and repeatable.

What types of linear units are there?

Linear units come in various types. The following types are the most typical:

- Linear roller slideways

- Single tube linear unit

- Double tube linear unit

- Telescope linear unit

- Spindle guides

Linear roller slideways are frequently used to move heavy parts such as manipulators. A paired, parallel design has proven itself here. One important consideration for this type of linear unit is regular, conscientious lubrication. Single tube linear units are used for quick adjustment of sensors or other light components. They are available with round or square tubes. Round tube linear units allow rotation of the attached part around the tube axis. Square linear units are an inexpensive solution for rotationally stable designs.

Double tube linear units also offer quick, manual adjustability. However, they do not permit rotation and hold the moved element in exactly the desired position.

Telescope linear units are flanged on only one side, allowing them great flexibility. Spindle guides can be controlled with particular precision. This makes them the standard linear unit design for sensitive applications such as machine tools or 3D coordinate measurement systems.

INOCON’s selection of linear guides can be round HERE. The standard design is made of steel. INOCON offers single and double tube linear guides. For applications with challenging hygiene requirements, such as in the food and pharmaceutical industries or laboratory technology, linear guides of stainless steel are also available. With matching clamps and tube connectors, the linear guides can be extended as needed and adapted to the specific application.

Why choose INOCON linear units?

INOCON offers its customers a modular system of high-quality individual parts. The linear guide units are perfectly adapted to the other products, such as tube connectors and clamps.

INOCON is specialized in the production of single and double tube linear units. These technically simple products offer impressively high reliability and maximum flexibility. They can be moved either manually or by motorized drives. The precision of INOCON linear units can be adapted to the specific needs of the user. The guides are suitable for rough positioning work as well as applications with tight tolerances.

INOCON manufactures its products in industrial grade quality, true to the made-in-Germany tradition. With their reliability, stability under load and large reserves, all INOCON linear units earn the trust of their users. Designers looking for a long-lasting solutions will therefore find precisely what they need in the products from INOCON.

Contact

Do you have special challenges in the area of research and development? Contact us. We look forward to your inquiry and will help you find just the right solution for your application.