Connecting square tubes – options and variants

Square tubes are especially popular for building stable frames and stands. They offer high torsional stiffness and create robust frameworks. The right-angled sides of the tube sections ensure that the construction can be expanded as needed at any time. This makes square tube sections especially versatile.

What materials can be used to connect square tubes?

Because square tubes are generally used for sturdy frame constructions, selecting the right material is critical. The following materials have proven themselves for the manufacturing of square tubes: Steel, stainless steel, and aluminum.

- Normal construction steel offers outstanding strength at a low price.

- Stainless steel does not rust and is non-magnetic. It is especially suited for hygienically challenging environments and is also visually appealing.

- Aluminum is light and flexible. It is also immune to corrosion and can be polished to a mirror finish. This metal is ideal for detachable square tubes

- Connections that do not have to withstand high loads.

The following types of connections are available:

- Detachable

- Permanent

The possible connection methods are:

- Screwing

- Inserting

- Clamping

For detachable connections, any material can be chosen for the connecting element. For permanent connections, the following methods can be chosen:

- Welding

- Gluing- Soldering

- Riveting

For welded and soldered connections, the connecting elements should be of the same material as the base material. For glued and riveted connections, any material can be selected.

How do I connect aluminum rectangular tubes?

Rectangular tubes of aluminum can be easily bolted or riveted. However, welding of aluminum is a challenge that requires appropriate equipment and qualifications. Detachable clamp connections are therefore the optimal choice for rectangular tubes of aluminum.

What advantages do clamp connections offer in relation to square tubes?

Clamps are available as internal or external clamps. Both versions offer the following advantages:

- Connecting and disconnecting of square tubes without damage

- Large selection of angles - Easy handling

- High holding force when assembled correctly- Suitable for high shearing forces

- Invisible connection when using internal clamps

Only a basic hex key or hex socket wrench is required for installing clamp connections. The connectors can be installed and removed again as often as necessary. This makes them ideal for temporary uses, such as in stage or trade fair booth construction.

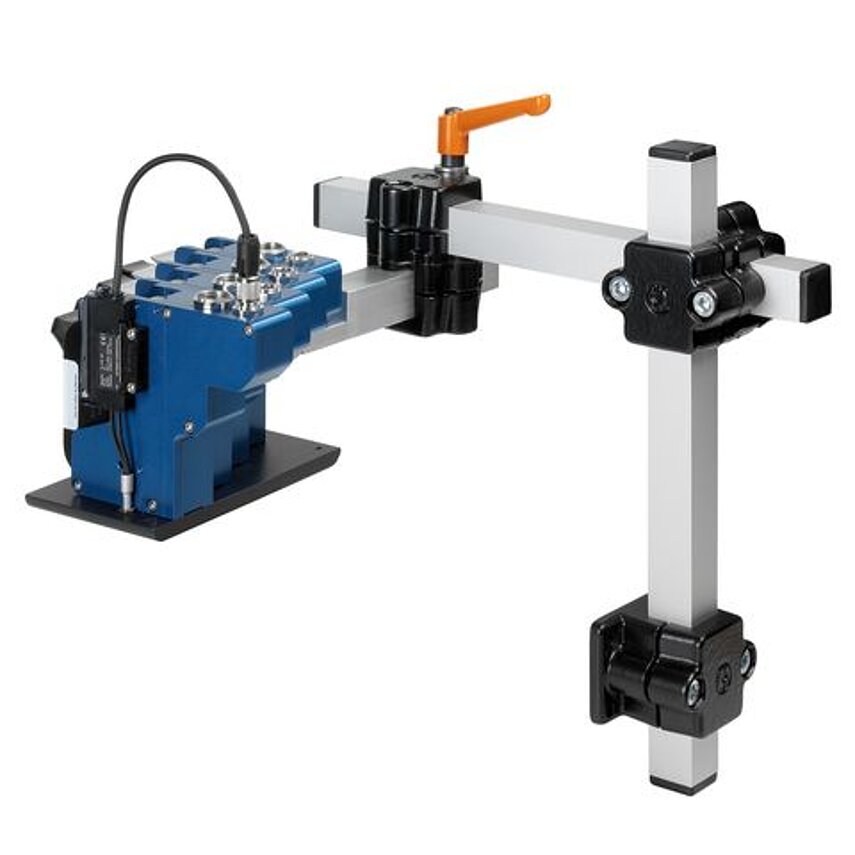

Connecting square tubes with swivel clamps

Swivel clamps are freely clamping elements with a protruding lug that allows them to be freely positioned. They offer the following advantages and disadvantages:

| + Simple fastening elements for lightweight parts |

| + Any positioning is possible |

| + Very versatile |

| - Not suitable for holding loads |

| - Risk of injury |

Tube supports for connecting square tubes

Tube supports for square tubes are used to mount the tube or the finished tube construction at a specific place of use. They offer the following advantages and disadvantages:

| + Simple solution for universal fastening |

| + Easy and flexible handling |

| + Any positioning |

| + Durable and robust |

| - Small cross-section can cause pressure points in the tube section |

| - Risk of breakage in the event of rust |

Connecting small square rubes with clamp mountings

Clamp mountings are used for tool-free, flexible positioning of attachments on square tubes. They offer the following advantages and disadvantages:

| + Simple installation |

| + Available in many sizes |

| + Tool-free handling |

| - Limited usability |

| - Not suitable for sustained loads |

| - Can be dislodged by vibrations |

Summary

Tube connections are either detachable or permanent. A large selection of parts are available for detachable connections. Only a few tools are required for installation. With the right selection of tube connectors, it is possible to built any imaginable design.

Contact

Do you have a special challenge in the field of research and development? Then contact us! We look forward to your inquiry and will help you find just the right solution for your application.